Frequently Asked Questions

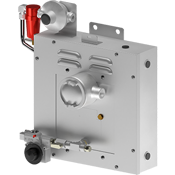

How do Catco Heaters work?

Catco heaters use a chemical reaction to generate heat without a flame. This chemical reaction requires three things: Fuel gas (natural gas or propane), Preheated Catco catalyst (catalyst preheated to approximately 250°F with an electric heating element) and oxygen (from ambient air). Our heaters are designed so that these three elements come together at the face of the heater to produce heat.

What makes Catco heaters safe?

First and foremost, Catco heaters are completely flameless from start up to shut down. Additionally, when in operation, Catco heaters have been found to be non-incendiary when directly exposed to flammable or incendiary gasses.

While running at 100% output, Catco heaters have been directly exposed to several flammable substances including Methane (ignition point 1076°F), Propane (ignition point 878°F) Heptane (ignition point 419°F) and Gasoline (ignition point 536°F). In each case, no ignition of the fuel or fuel vapors occurred. Catco heaters are available with certifications for hazardous locations. Asbestos has never been used in any Catco product.

What is the life expectancy of the heater?

The life of a catalytic heater is very dependent on gas quality and environment. The catalyst is not consumed during the chemical reaction, so in an ideal world, they would last forever. In real life applications however, we have seen them last anywhere from two to 15 years.

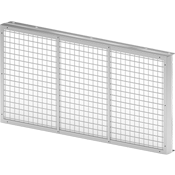

What steps do I need to take to maintain my Catco heater?

Catco heaters contain no moving parts and maintenance is minimal. The face of the heater should be protected from water and other contaminants. If an area is being cleaned with high pressure water spray or air pressure, care must be taken to protect any heaters in the area, as the catalyst may be damaged or destroyed. When the heater is not in use, it should be stored in a clean, dry area. Heaters should be wrapped in plastic or other protective material when not in service to protect them from excessive contaminants and rodent or insect damage.